Laboratory ovens are indispensable tools in pharmaceutical research, offering precise temperature control, uniform heating, and reliable performance. In Indonesia, where the pharmaceutical industry is rapidly expanding, laboratory ovens play a pivotal role in supporting research and development (R&D), quality control, and experimental reproducibility. From drug formulation to stability testing, these devices ensure that laboratories operate efficiently, safely, and in compliance with international standards.

Understanding Laboratory Ovens

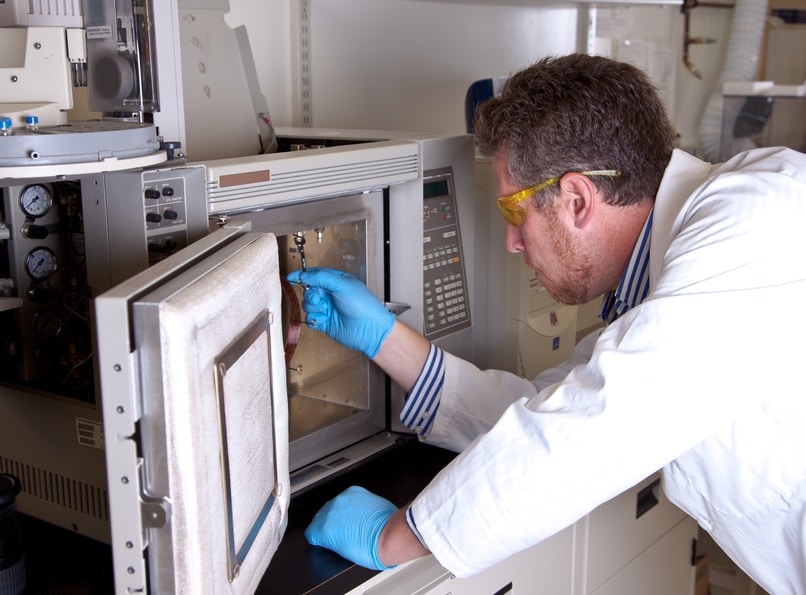

Laboratory ovens are designed to provide consistent, controlled heating for a wide range of scientific applications. Unlike conventional ovens, they are specifically engineered to maintain precise temperatures over extended periods, making them suitable for sensitive pharmaceutical experiments. Key features of laboratory ovens include uniform heat distribution, adjustable temperature settings, rapid heating, and safety mechanisms to prevent overheating or contamination. In pharmaceutical research, such features are essential to guarantee the accuracy and reproducibility of experimental results.

Applications in Pharmaceutical Research

In Indonesia’s pharmaceutical laboratories, laboratory ovens are employed across multiple stages of drug development. One primary application is drying and sterilisation of glassware and instruments. Contaminants or residual moisture can significantly affect experimental outcomes, so ensuring that all equipment is free from impurities is critical. Laboratory ovens provide a reliable method to achieve this, offering controlled heat that eliminates microbial contamination and moisture without compromising the integrity of sensitive tools.

Another significant application is in sample preparation and formulation studies. Many pharmaceutical compounds require precise drying, curing, or heating to achieve optimal physical and chemical properties. Laboratory ovens facilitate these processes by providing stable and uniform heating, which is essential for consistent formulation of tablets, capsules, and topical products. By enabling precise control over temperature and time, ovens help researchers develop formulations that meet both efficacy and safety standards.

Stability Testing and Quality Control

Stability testing is a crucial aspect of pharmaceutical research, ensuring that drugs maintain their intended potency, safety, and quality throughout their shelf life. Laboratory ovens are frequently used to simulate accelerated ageing conditions, exposing pharmaceutical samples to controlled heat to monitor chemical stability. This allows researchers to predict how drugs will perform under various storage conditions, a process essential for regulatory compliance and market approval.

Additionally, laboratory ovens support quality control testing, including moisture content determination, sterilisation validation, and thermal analysis. Consistent and accurate temperature control ensures that test results are reliable and reproducible, reducing variability and enhancing confidence in the data. In Indonesia, where the pharmaceutical market is becoming increasingly competitive, maintaining rigorous quality control is vital for meeting both domestic and international standards.

Supporting Innovation and Research Efficiency

Beyond routine testing and sample preparation, laboratory ovens contribute significantly to innovation in pharmaceutical research. Modern ovens often incorporate digital controls, programmable timers, and advanced airflow systems, allowing researchers to conduct complex experiments with minimal human error. This not only saves time but also enhances research efficiency, enabling laboratories to handle a larger volume of experiments and accelerate drug development timelines.

For academic and industrial research institutions in Indonesia, laboratory ovens also support formulation optimisation and experimental reproducibility. By providing a controlled environment for heating and drying processes, these ovens reduce experimental variability, allowing researchers to focus on innovation rather than troubleshooting inconsistent results. This is particularly important in pharmaceutical research, where even minor deviations in processing conditions can lead to significant differences in drug performance.

Safety and Compliance Considerations

Safety is a fundamental concern in pharmaceutical laboratories, and laboratory ovens are designed with this in mind. Features such as over-temperature protection, insulated chambers, and alarms help prevent accidents and ensure the safety of personnel. Compliance with local and international standards, including Good Laboratory Practice (GLP) and ISO certifications, is also critical. Using high-quality laboratory ovens helps Indonesian laboratories meet these regulatory requirements, providing assurance to stakeholders and regulatory authorities.

Choosing the Right Laboratory Oven

Selecting the appropriate laboratory oven for pharmaceutical research depends on several factors, including temperature range, chamber size, airflow type, and specific application requirements. Forced-air convection ovens, for instance, are ideal for uniform drying and sterilisation, while vacuum ovens are suitable for heat-sensitive materials that require low-temperature drying. By choosing the right equipment, Indonesian laboratories can optimise experimental outcomes and ensure efficient, safe operation.

Conclusion

Laboratory ovens are more than just heating devices; they are essential instruments that underpin the accuracy, safety, and efficiency of pharmaceutical research. In Indonesia’s growing pharmaceutical sector, these ovens support critical processes such as sample preparation, stability testing, and quality control, while enabling innovation and experimental reproducibility. By investing in high-quality laboratory ovens, researchers and laboratories across Indonesia can enhance the reliability of their studies, accelerate drug development, and contribute to the advancement of the nation’s pharmaceutical industry.